Evolving Conveying Technology Prioritizes Food Safety and Durability

November 15, 2023

Like other processes in meat packing, processor concerns involving the motors that run their conveyors tend to revolve around efficiency, reliability, longevity, sanitation, and how it stands up to washdown cycles during the sanitization routine.

Read More

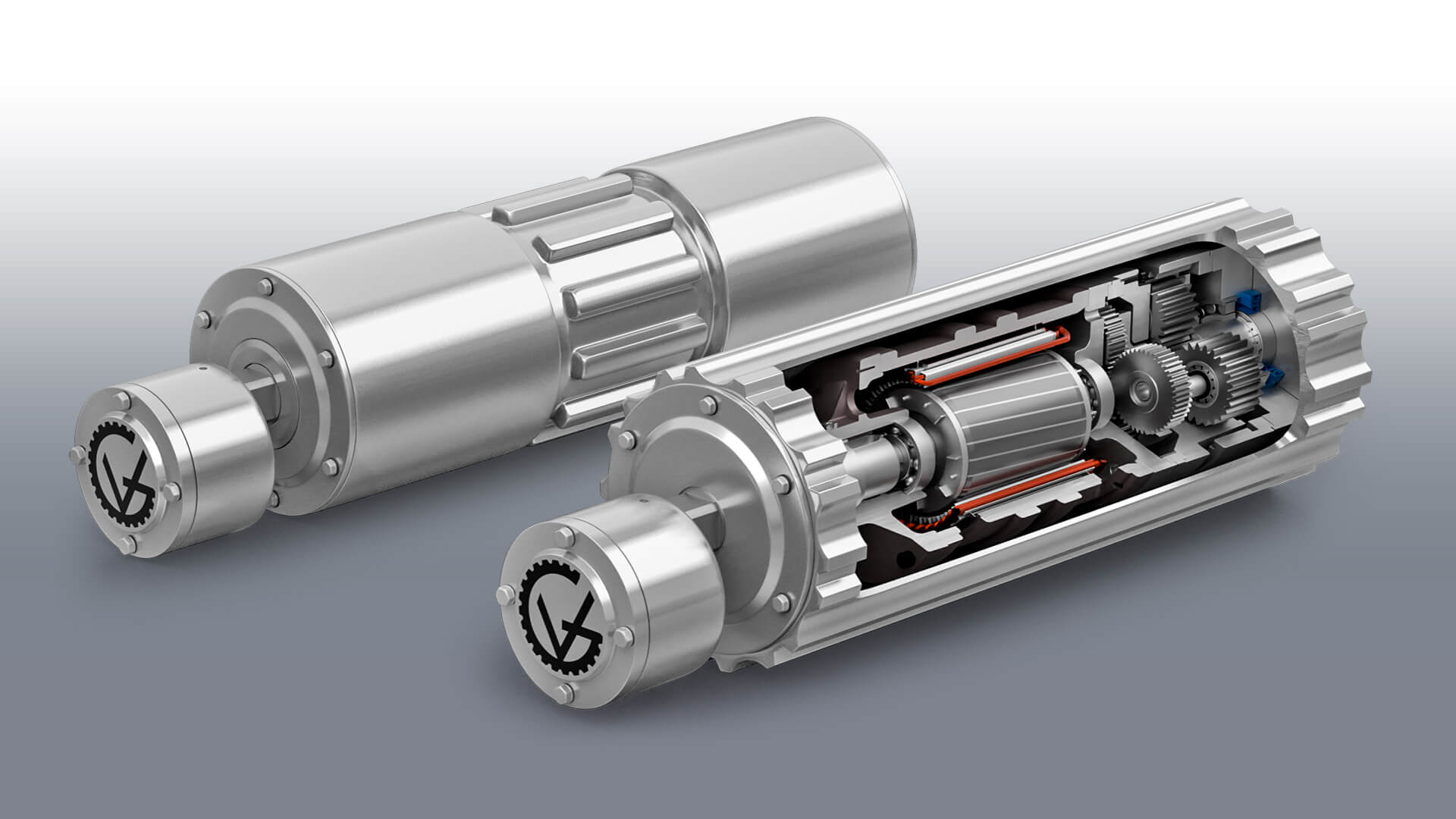

A New Generation of Reliable Drum Motors

October 09, 2023

The drum motor, used to power conveyor belts since the 1950s, operates safely and is often a space saver. But they haven’t gained traction with the belt conveyor industry because the internally powered conveyor drives tended to overheat. But that changed in mid-2021.

Read More

Manufacturers Optimistic for 2023 Despite Challenges

January 03, 2023

Equipment manufacturers have an overall positive outlook for 2023, and share their thoughts on some challenges from last year will persist.

Read More

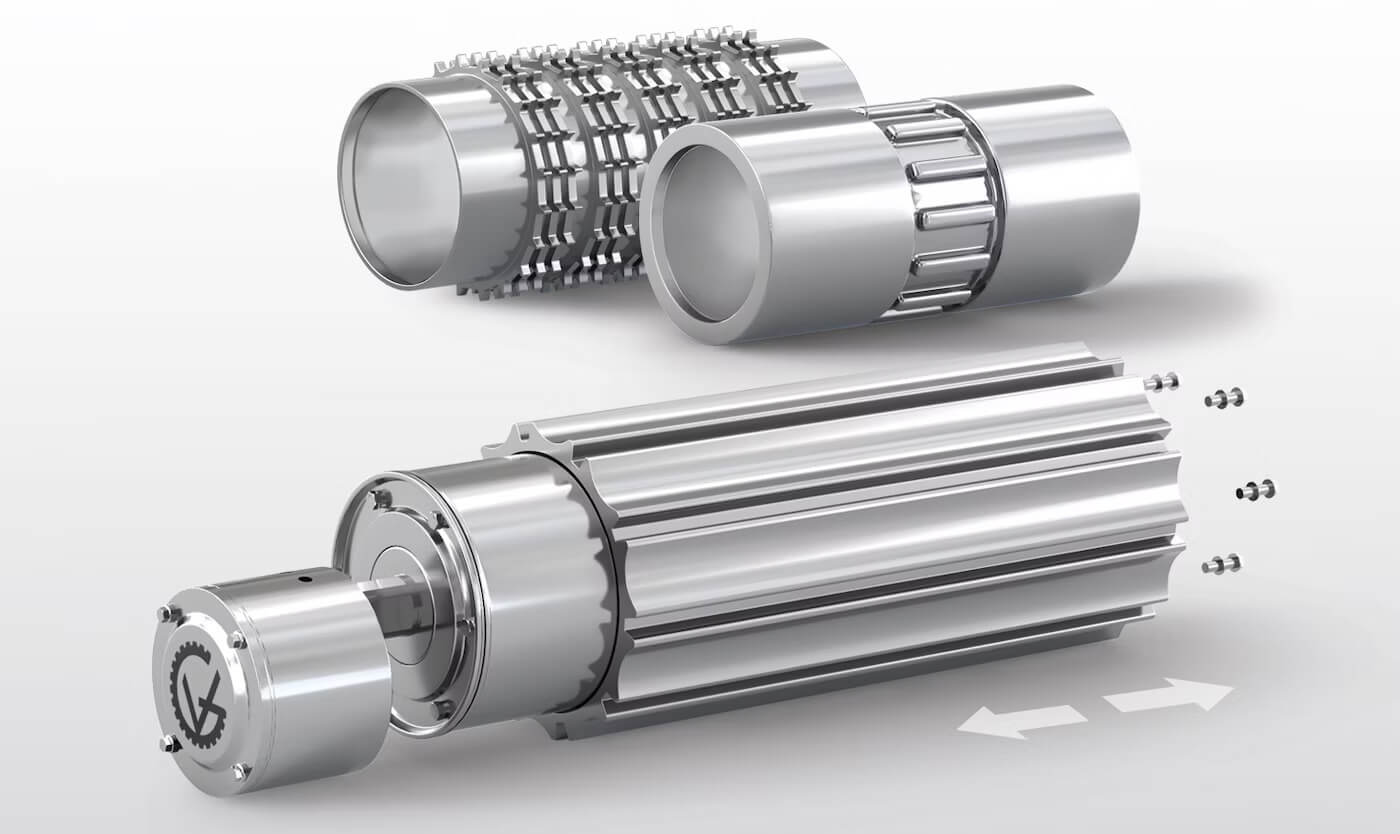

Exchangeable Continuous Profile Drum Motor Sleeves Provide Flexibility

November 03, 2022

Easily swap the continuous profiled sleeve for another sleeve with a different type of profile, by simply removing only six screws from the drum motor end flange.

Read More

Drive Reliability in Your Baggage System

February 07, 2022

Upgrading an airport baggage handling system offers airports a unique opportunity to address

operational reliability, sustainability and a better passenger experience knowing luggage will get to the travelers in a timely fashion.

Read More

Rock Products' Quarry & Aggregates Forum

January 03, 2022

Rock Products presents the second part of its Annual Q&A Forum, with manufacturers discussing equipment and technology.

Read More

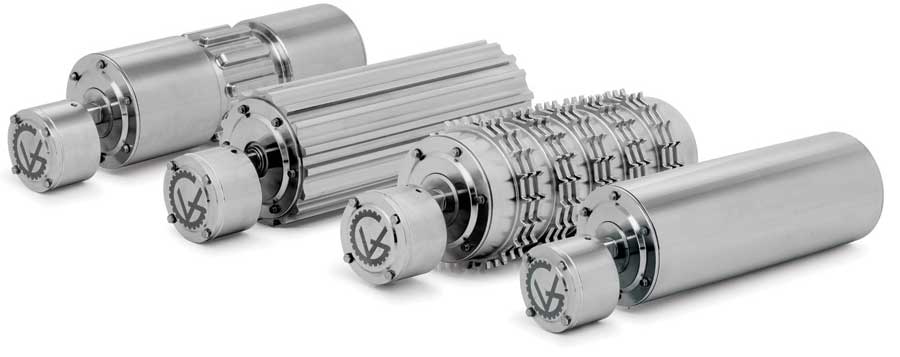

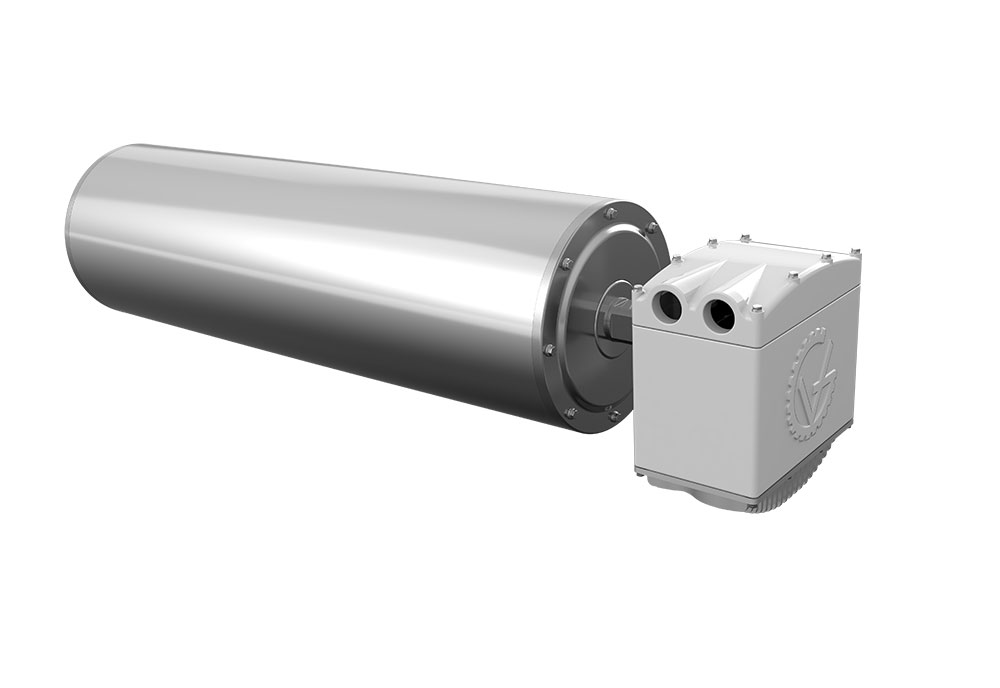

Sanitary Series Product Line Update

April 28, 2021

Effective January 1, 2022 - VDG will stop the production of the three-rod drive drum motors, UHMW sprockets, stainless steel sprockets, and continuous profile on urethane base material. VDG will continue to support and provide replacement units and parts until January 1, 2024.

Read More

Adding safety, security around conveying systems

October 08, 2019

Ensure conveyor guarding can mitigate safety risks, says Van der Graaf’s Matt Lepp

One of the most common issues related to safety as seen across aggregate manufacturers is the guarding of moving components in a conveyor system.

Read More

Effective conveyor, material handling maintenance practices

October 08, 2019

Proper analysis of maintenance-intensive parts and available solutions can go a long way to reduce time and money spent on conveyor system maintenance. With the wealth of new technologies available to the aggregates market today, many solutions are readily available to replace existing high-maintenance parts with low-maintenance or maintenance-free options, thus lowering costs and increasing system uptime.

Read More

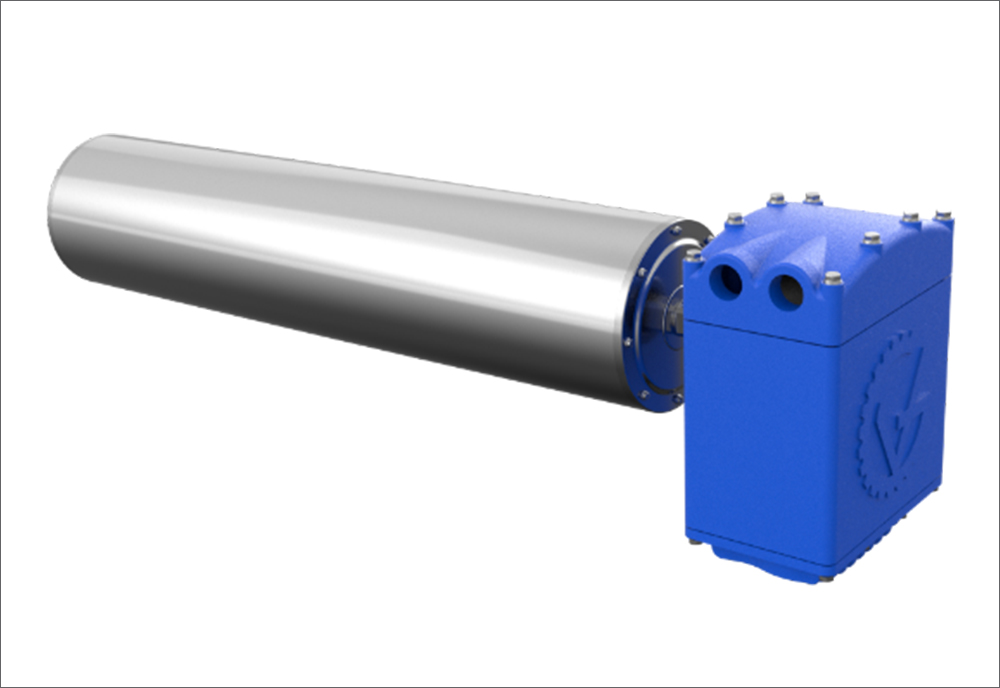

Sanitary Drum Motors from VDG create ROI

August 23, 2019

Van der Graaf, a global manufacturer of drum motors located in Brampton, Ont., says its line of SSV series sanitary drum motors is available in five versions: TM100, TM113, TM127, TM160, and the TM215, with drum diameter and horsepower differences, but each advancing food safety and worker safety. Other options are available for each of these drums.

Read More

Conveyor solutions extend beyond original equipment

May 13, 2019

In beverage processing and packaging operations, each step is dependent upon operating in sync with one another in order to ensure that all processes work properly. To help keep operations on task, beverage manufacturers and distributors are seeing an increased need to have accumulation systems support their conveying solutions.

Read More

ProMat 2019 help companies find their “WOW”

May 13, 2019

More than 950 exhibitors, nearly 150 on-floor informational seminars and a host of materials handling technologies, supply chain solutions and automation innovations were displayed in 420,000-square-feet of exhibits across two halls at ProMat 2019, which took place April 8-11, at McCormick Place in Chicago. Sponsored by Material Handling Institute (MHI), ProMat again was co-located with Automate 2019, sponsored by the Association for Advancing Automation.

Read More

Ongoing sanitary design advances for snack and bakery equipment

March 21, 2019

Manufacturers and equipment providers continue to collaborate to set the sanitary design bar higher.

To address ever-present and continuously growing sanitation-related concerns across the snack and bakery industry, equipment manufacturers are working to provide machinery that’s easy to wipe down, doesn’t provide harborage for moisture or stray ingredients, and is simple—ideally tool-less—to disassemble and reassemble as needed.

Read More

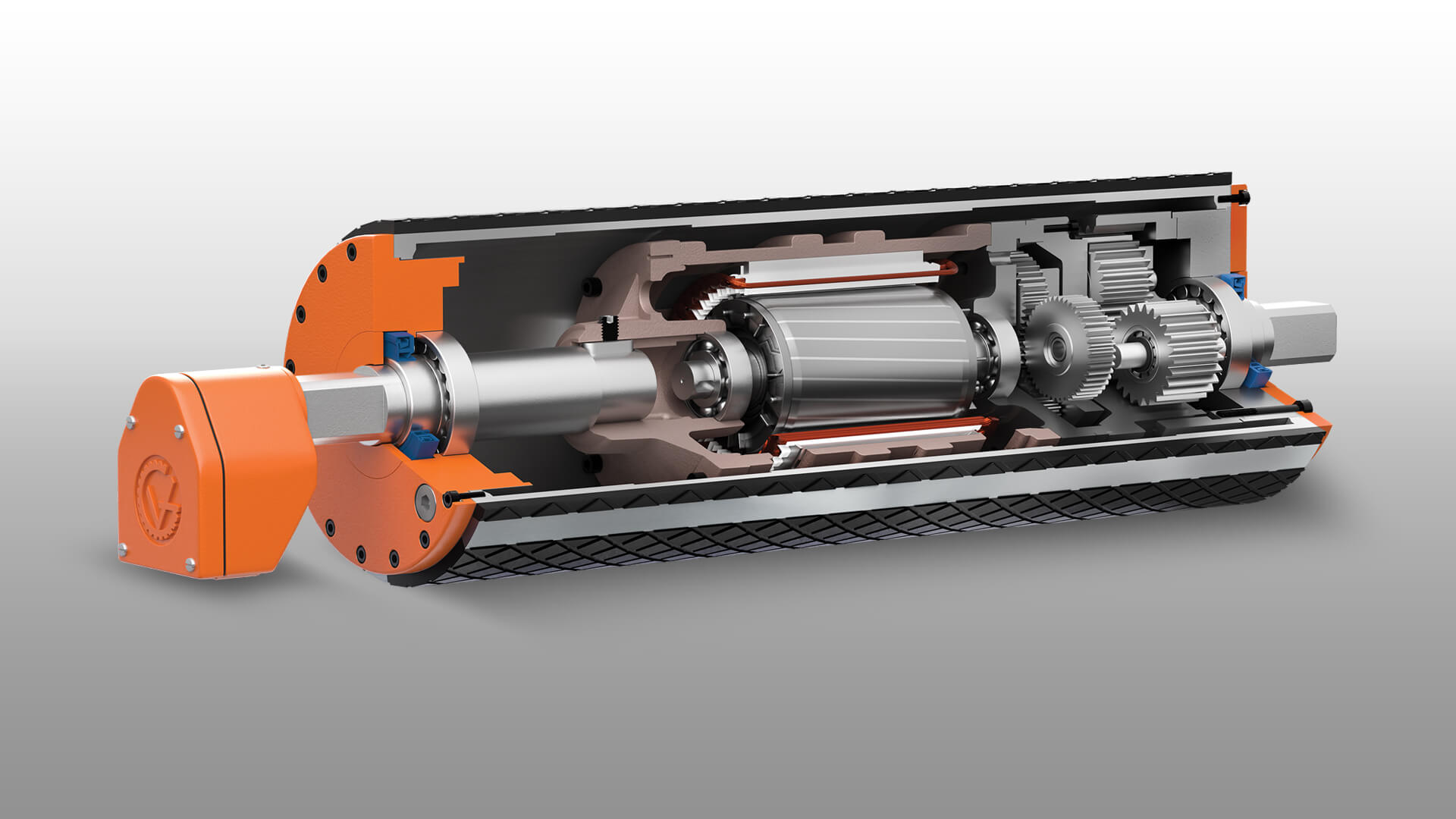

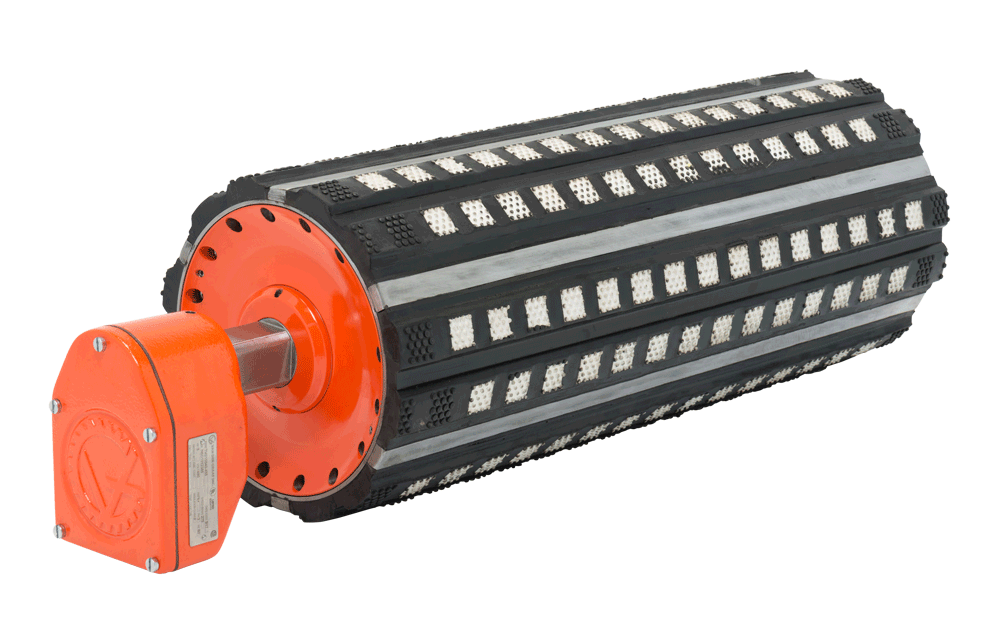

Drum motors for extreme operating environments come under the SME spotlight

February 24, 2019

Alexander Kanaris, President of Van der Graaf, will put forward the benefits of using the company’s GrizzlyDrive™ drum motor with IronGrip lagging in extreme environments at the SME Annual Conference and Expo on Monday.

In an abstract ahead of the conference, Kanaris said: “Conveyors powered by external motors and gearboxes, along with v-belts, chains, couplings and pillow block bearings, often operate with relatively low efficiency and require regular maintenance.

Read More

Motors and Related Equipment Become More Versatile

February 21, 2019

Variable-frequency drives and other components help make electric motors more versatile and effective.

Equipment is powered by motors. And increasingly, so is equipment innovation.

Improvements in electric motors, and in the drives and controls that regulate them, are enhancing the versatility and flexibility of conveyors and other food plant equipment. As they become more powerful and more capable of handling varied loads and tasks, they open new possibilities of economy, quick response and better overall performance.

Read More

Using data to make the most of automation, IIoT and AI on the manufacturing line

February 14, 2019

The workhorses of any food processing line are the motors and drives that allow so many moving parts to run in concert.

Those motors and drives run the food and packaging production lines that processors rely on, and they are a major consideration of any automation strategy. Automation, the industrial internet of things and artificial intelligence all start with data. It’s all about data collection, data management and knowing what to do with that information. A strategy for connecting everything in a plant to make data-driven decisions has to include the motors and drives.

Read More

New and improved belts and conveyors for snack and bakery production facilities

January 10, 2019

Snack and bakery companies seek improvements to capacity, energy efficiency and safety in their belts and conveyors.

Snack food and bakery companies looking to purchase belts and conveyors are asking for larger capacity, quieter machinery, improved safety, greater energy efficiency the ability to reduce manpower—and, thus, costs. They’re also looking for easier and more-predictable cleaning and maintenance.

Read More

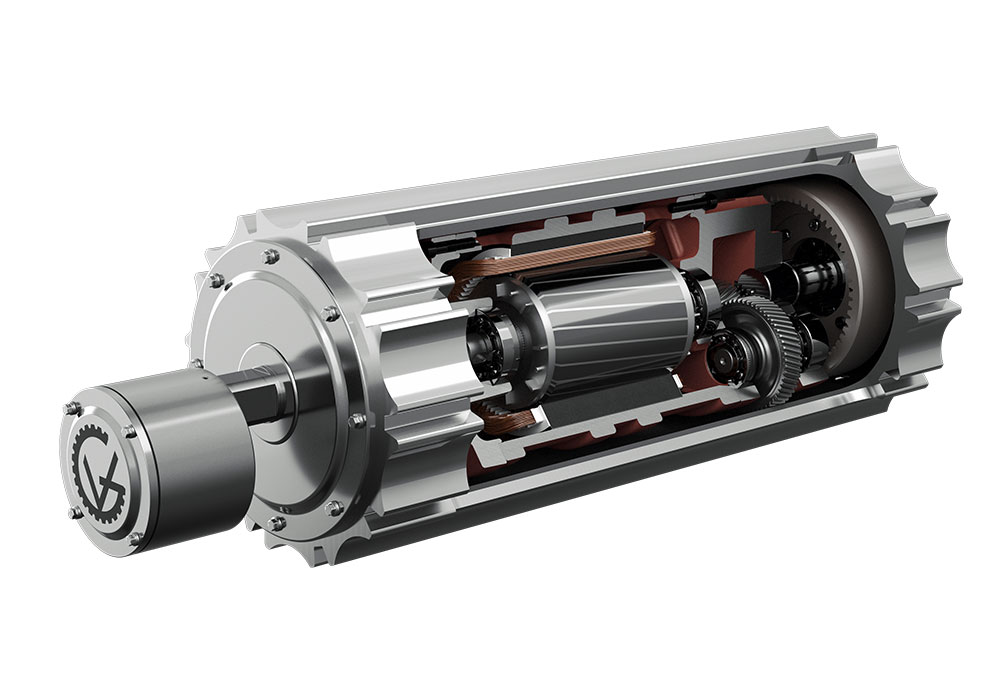

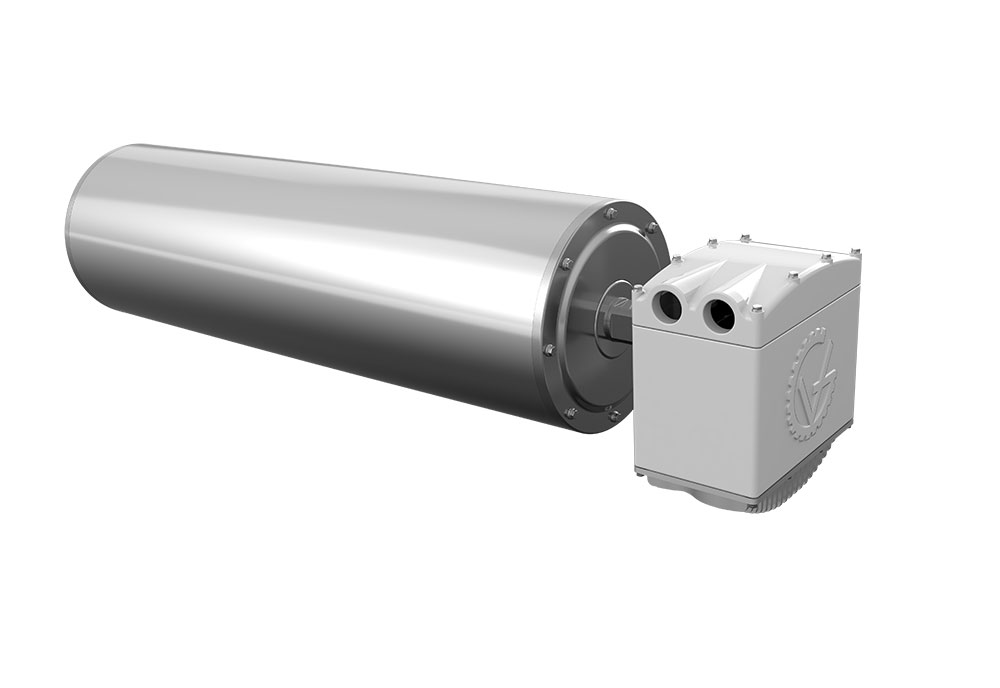

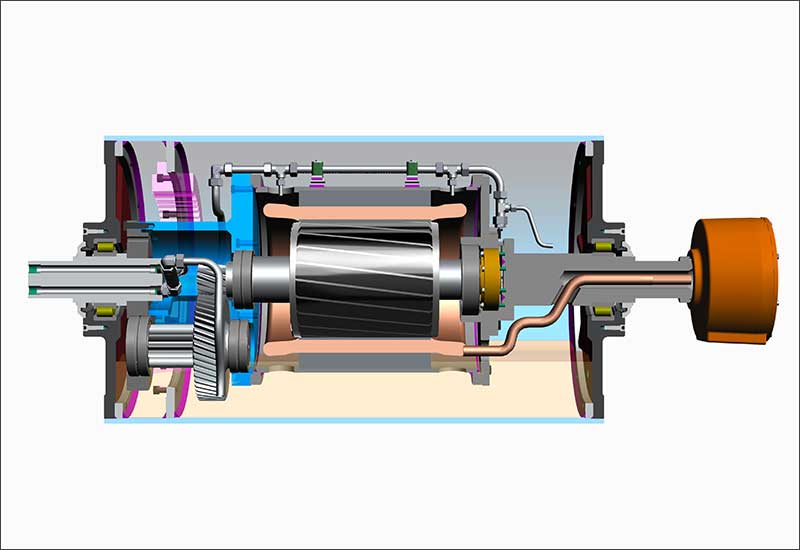

Van der Graaf: Motor Consumes Less Energy

September 13, 2018

Intelligent Drum Motor technology delivers high efficiency and data feedback communication.

Conveyor users and conveyor manufacturers have accepted the drum motor as the most efficient way to drive belt conveyors. With no external motor and gearbox, the drum motor saves space, eliminates the need for scheduled maintenance and enhances operator safety.

However, the challenge has been the ease and ability to adjust belt speed as plant processing requirements change. This is achieved via a frequency inverter (VFD), which often is located in a control room some distance away from the conveyor drive electric motor.

Read More

Van der Graaf develops intelligent drum motor technology

July 17, 2018

Van der Graaf announced it will soon release a new Intelligent Drum Motor (IDM) technology which is designed to deliver high continuous torque profile, full speed and indexing control, and significant energy-efficiency gains over traditional induction motors.

Read More

Motor And Drive Innovations Give Food Manufacturers More Power Options

February 21, 2018

Moderate-cost condition monitoring sensors and housings designed for optimal cleaning and sanitizing are among advancements in power systems.

Powering production in food plants is not as simple as throwing a switch. Peak-time charges, outages, surges and other factors can complicate calculations of cost and reliability and require solutions that go beyond standardizing on premium motors.

The good news is that OEMs are delivering solutions on multiple fronts, from systems approaches to power delivery and servo options to sanitary design improvements and smart motors.

Read More

Producer completes modernization project with conveyor drives

January 19, 2018

Carmeuse successfully completes a modernization project involving conveyor drives at two Michigan operations.

As Carmeuse Lime & Stone systematically modernizes its plants in the Great Lakes region, opportunities arise to marvel one last time at the longevity provided by the century-old equipment the company is replacing.

Similar examples could be found at Carmeuse’s Calcite operation in Rogers City, Michigan, and the Port Inland operation on the Upper Peninsula in Gulliver.

Read More

Drum motors improve electrical and mechanical efficiencies

January 08, 2018

Compared to conventional drive systems, drum motors powering a conveyor will pay for themselves.

PACK EXPO Las Vegas visitors had the opportunity to watch a demonstration of the fundamental differences between powering a belt-conveyor with Van der Graaf’s drum motor versus a conventional drive system.

“Comparison of the external motor and gearbox to that of the drum motor measures the efficiencies, and the electrical savings as a result of the comparison,” explained Rick Zander, business development manager at Van der Graaf. At the Vegas demo, the external motor was mated to a 90-degree gearbox, which was then powered to the conveyor.

Read More

Van der Graaf drives help Taylor Farms reduce failures

December 22, 2017

Plant achieves better sanitary results and more reliable production.

Taylor Farms, a California-based producer of salad kits and other fresh-cut, packaged vegetable products, has long been an industry leader in food safety and quality standards.

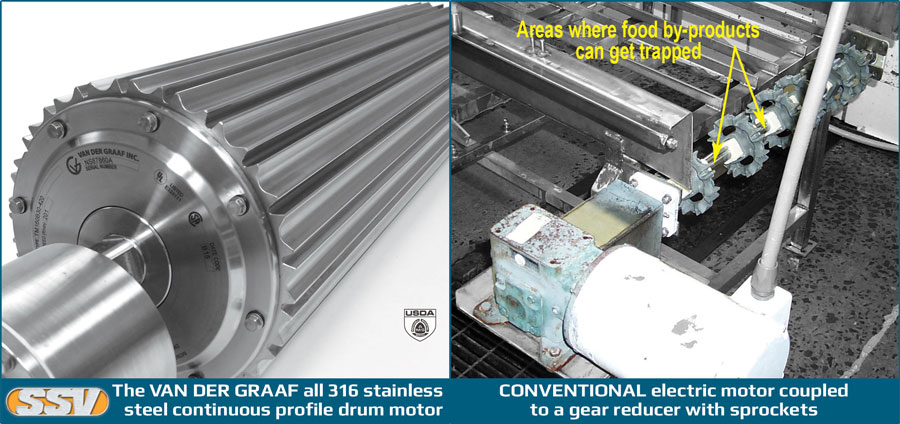

Part of its food safety efforts requires sanitizing conveyors and conveyor drives. But with so many nooks and crannies for food and other materials to fall into, cleaning had been a time- and labor-intensive task.

Read More

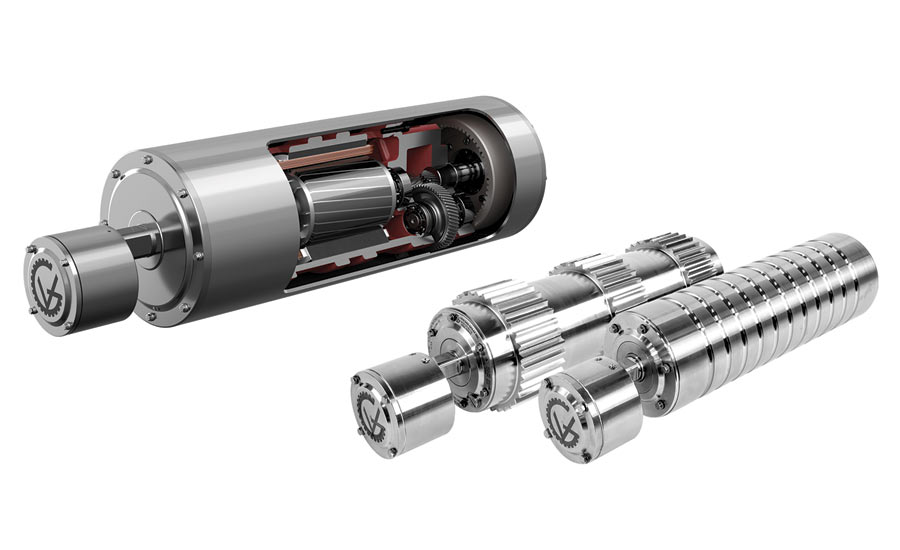

Van der Graaf Drum Motors Require No Maintenance

October 24, 2017

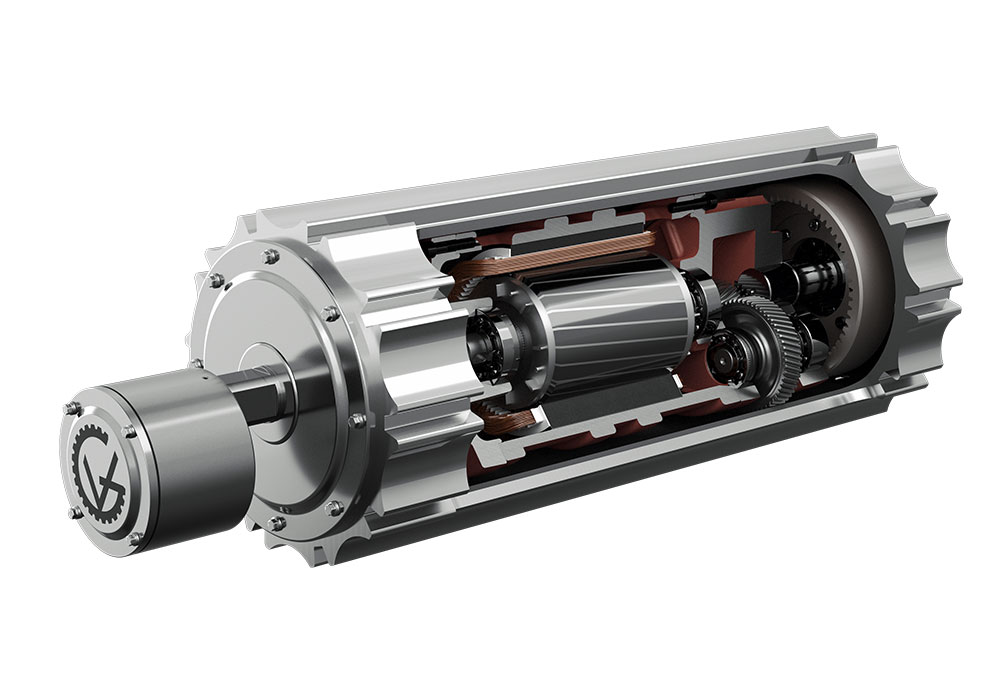

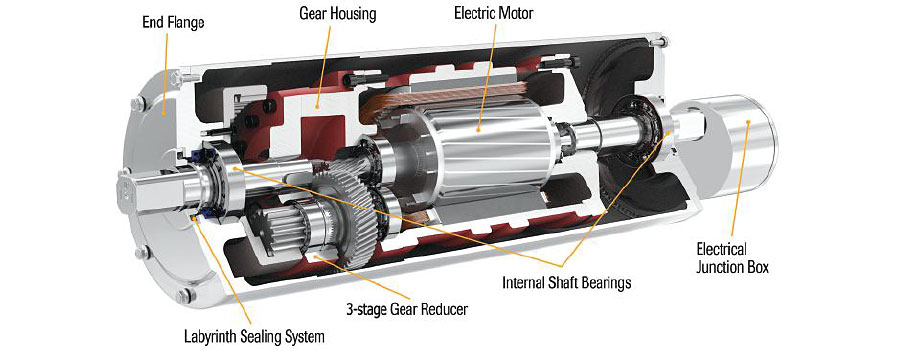

A drum motor is a one-component conveyor drive where the motor, gear drive and all moving parts are enclosed inside the drum. The motor and gears operate in a sealed oil bath ensuring proper lubrication and cooling. With no external motor, gear reducer, sprockets, chain or required chain guard, no external component maintenance is required.

For more than 30 years, Van der Graaf has been the leading manufacturer of drum motors for belt conveyors in material handling and processing applications. The rugged, extreme-duty drum motors are available up to 350 hp and 36-in. diameter, with a variety of lagging options to provide a durable drive with a long service-life. Drum motors have a safe and worry-free design that withstands the harshest conditions and reduced operating costs.

Read More

Rockin’ The Rails

June 28, 2017

Georgetown Rail Equipment Co. Delivers a Lot of Aggregate with the Help of Van der Graaf Extreme-Duty Drum Motors.

When Ned Snead founded the Georgetown Rail Equipment Co. (GREX) in 1993, he was aware that technology was transforming the rail industry. That led him to invent the DumpTrain aggregate delivery system. It was a breakthrough in productivity, capable of delivering more than 2,000 tph of ballast with pinpoint accuracy using a single operator.

Ten years later GREX introduced a new innovation called Aurora. This 3-D track inspection system uses laser technology and state-of-the-art cameras to spot track and tie flaws before they cause costly problems.

Read More

Van der Graaf Holds Drum Motor Seminars in Texas

May 05, 2017

Van der Graaf held several seminars in Texas to demonstrate to local aggregates producers how to optimize the efficiency, operating costs and safety of drives. The seminars were held in Fort Worth and New Braunfels. Rock Products was on-hand to participate in the Fort Worth session.

Matt Lepp, heavy industry drive specialist, told the group that the company’s extreme-duty drum motors “excel in applications that are dusty and dirty.”

Lepp talked about the company and its capabilities, and told attendees about the benefits of Van der Graaf drum motors. “There are many reasons why this is a superior product,” he said. “Beside the use of premium materials in the manufacture of these products, they are also very durable.”

Read More

Van der Graaf kicks off educational event series in Texas

May 03, 2017

Van der Graaf hosted the first of its industry networking events Wednesday in Texas.

The company’s kickoff event took place in Fort Worth, Texas. Van der Graaf’s Texas Aggregate Networking Event series continues Thursday in New Braunfels, Texas.

“With Texas being the largest, single-producing state for stone, sand and gravel in the U.S., we’re going around promoting our Extreme-Duty series, which is going up to 350 hp and 36-in.-diameter drives,” says Matt Lepp, heavy industry drive specialist at Van der Graaf. “These are specifically designed for heavy industry applications.”

Read More

Food Processors Gravitate To New Conveyor Drive Options

April 14, 2017

Multiple considerations and trade-offs are in play when food processors determine what kind of conveying technology is best for their operations.

Drum motors are a rarity once food is safely tucked away in its primary package, but they are becoming the drive technology of choice in the processing zone and raw-materials handling areas. Hygienic considerations are driving the shift from gear motors, though not all manufacturers consider drums a food safety cure-all.

Read More

Drum Motors 101

March 30, 2017

An Aggregates Plant is a Perfect Environment for a Drum Motor. But Why is the Drum Motor a Better Solution than an Exposed Drive?

A drum motor is a one-component conveyor drive where the motor, gear drive and all moving parts are enclosed inside the drum. The motor and gears operate in an oil bath ensuring proper lubrication and cooling. With no external motor, gear reducer, sprockets, chain or OSHA required chain guard, no external component maintenance is required. We asked Heavy Industry Drive Specialist Matthew Lepp at Van der Graaf to talk a little bit about the product.

Read More

FSMA prompts changes in belt conveyors

November 11, 2016

Conventional designs pose potential hygienic hazards.

As regulations and standards associated with the Food Safety Modernization Act (FSMA) take effect, food processors are looking at their operations to identify risks. One area of concern is the belt conveyor and its external motor and gearbox drives, which are commonly used to move unprocessed and processed food around a plant. These designs pose potential hygienic hazards.

Read More

A Superior Drive Solution

October 07, 2016

With food safety being a continuous concern for food-processing facilities, conveyor equipment manufacturers are continuously looking for better solutions for preventing bacteria build up and food contamination.

The continuous all stainless steel profile drum motor is part of the Van der Graaf SSV sanitary drum motor series. Specifically designed to power food processing conveyors; available in a wide range of diameter and horsepower ratings. The inherent benefits of these sanitary drum motors driving modular belt conveyors have had a tremendous positive impact in the food handling industry.

As FSMA takes effect, food-processing facilities already utilizing drum motors are experiencing the benefits through improved sanitation, efficiency, operator safety, as well as reduction in maintenance and energy costs.

Watch it here

Thinking inside - and outside - the box

June 21, 2016

Drum motors are well suited to food and beverage conveying applications where motors should be out of sight, safe and clean.

Driving a conveyor head roller with a drum motor, which features a motor and gear box within the roller housing, is not a new concept. For around 70 years, this design has addressed space utilization issues by incorporating all external components inside the drum. However, the design has lacked the electrical and mechanical efficiency that can contribute substantially to energy savings and has been known to present some seal integrity issues.

Today, the practical drum motor designs used in food processing plants protect all vital motor/gearing components within an IP69K stainless steel enclosure. These motors can withstand up to 3,000 psi of washdown pressure, without scheduled maintenance. Outside-the-box-thinking led to this improved design, with the motor, gear reducer and bearings inside the box, making it safer and more energy efficient. Plus, since no rotating components or pinch points are outside the conveyor frame, the drum motor conveyor drive protects personnel working around the equipment.

Read More

The Van der Graaf SSV drum motors bringing sanitary solutions to new heights

January 04, 2016

The new all 316 stainless steel drum motor with an IP 69k enclosure can withstand 3,000 psi wash down pressure.

In food processing plants, implementing sanitation processes to battle bacteria has increasingly become more challenging. Equipment manufacturers are required to design food-processing machinery that minimizes crevices where bacterial can harbor. Belt conveyors transferring food products to a number of processing stations has become ground zero for bacteria deposits. For this reason, belt conveyors are required to undergo frequent wash-down cycles. The wash-down process is usually done by pressure washing belt conveyors with warm water mixed with cleansing chemicals in order to remove, kill, or neutralize harmful bacteria.

Read More

Sanitation improvements in conveyor system design

November 02, 2015

I have been working with foodprocessing plants for the better part of the last 30 years.

In today’s meat and poultry industry, the sanitary condition of the processing machinery is constantly under scrutiny in order to combat Listeria, E. coli and other types of bacteria that can penetrate the food chain.

In addition to food safety, worker safety is atop the list of primary concerns in plants. Improving workplace conditions by removing safety hazards is paramount to overall plant safety. In taking these steps, a plant can also advance its equipment safety and smart energy usage — two other areas of importance to operations.

Read More

Sanitary, reliable drum motor drives success.

September 23, 2015

Poultry processor strives to meet customer demands without sacrificing the highest hygienic standards, so minimizing downtime is a must.

A custom food processor, AlaTrade Foods provides large poultry processors with a service that requires intensive amounts of labor. AlaTrade Foods takes in the front-halves of chickens and debones and disassembles products based on customer specifications—whether it is for the breast meat, wings, tenders or dark meat. AlaTrade debones approximately 1 million fronts (approximately 2 million pounds) a week.

To meet customers’ requests while maintaining sanitation standards, AlaTrade leverages process efficiencies, cutting-edge technologies and superior customer service, which results in better quality, better yield and better response times for customers.

Read More

AlaTrade Foods uses drum motors to ‘drive’ efficiency, food safety

August 04, 2015

AlaTrade Foods is a custom food processor that services large poultry processors requiring intensive amounts of labor in processes such as deboning. AlaTrade Foods takes in front-halves of chickens and debones / disassembles them based on customer specifications; breast meat, wings, tenders and dark meat are deboned for further processing and institutional use. AlaTrade debones approximately 1 million fronts a week, which calculates to about 2 million pounds per week.

What makes AlaTrade Foods unique is its quick response time. A customer can make any change at any point during the day and AlaTrade is able to process that change on first or second shift and possibly have it done as quickly as the following day. To achieve a quick response time at the highest level of sanitation standards and customer specifications, AlaTrade leverages process efficiencies, cutting-edge technologies and superior customer service to deliver better quality, better yield and better response times for customers.

Read More

Must see exhibits: Van der Graaf

March 30, 2015

The year 2015 marks a milestone for Van der Graaf as we celebrate 30 years of drum motor manufacturing. In 1985, we started in a 3,500 square feet facility. Today, we have over 200,000 square feet of manufacturing space in USA and Canada utilizing the latest technology and CNC equipment. Our mission remains the same today as it was in 1985, to provide reliable solutions to the material handling industry, through innovation, precision-manufacturing processes and after sale service.

At Van der Graaf, we are committed to quality and efficiency, and this is reflected in our Extreme Duty drum motors designed specifically for harsh and abrasive environmental conditions of the mining and aggregate handling industry.

Read More

The New all stainless steel profile SSV Drum Motor for modular belt applications

December 15, 2014

In the past three years, Van der Graaf’s engineering team have been working on the development of a new drum motor concept, soon to be released, that will increase its longevity and safety, reduce operational cost and energy consumption. The Zero Pressure SSV Drum Motor is equipped with an all stainless steel pro�le drum to drive most common modular and �at extruded belts without using plastic sprockets. The exclusive sealing design has a much higher water ingress resistance and can withstand 2,500 psi washdown pressure. Further details available at the IPPE 2015 booth #B5829.

Read More