Drum motors for extreme operating environments come under the SME spotlight

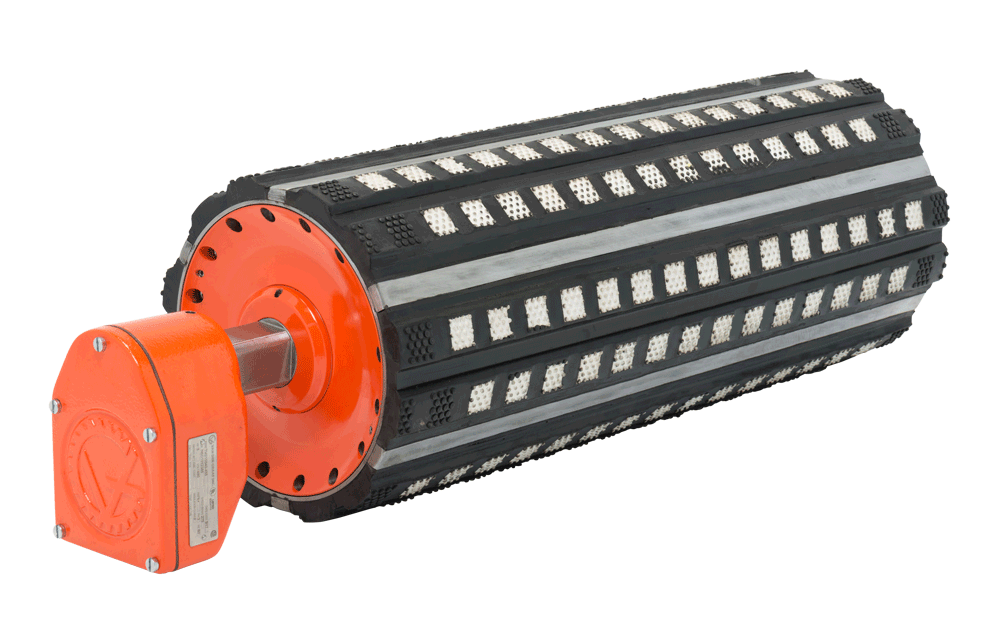

Alexander Kanaris, President of Van der Graaf, will put forward the benefits of using the company’s GrizzlyDrive™ drum motor with IronGrip lagging in extreme environments at the SME Annual Conference and Expo on Monday.

In an abstract ahead of the conference, Kanaris said: “Conveyors powered by external motors and gearboxes, along with v-belts, chains, couplings and pillow block bearings, often operate with relatively low efficiency and require regular maintenance.

“With rising electrical and labour costs, mining and aggregate industries are forced to evaluate ways to minimise downtime, reduce maintenance costs, increase worker safety and ultimately increase profits.”

According to Kanaris, new drum motor technology has addressed efficiency and operator safety concerns. An internally driven conveyor drive, the drum motor “eliminates external components, houses the electric motor and gearbox inside the drum, increases operator safety, saving space, eliminates scheduled maintenance, increases longevity and overall efficiency”, Kanaris said.

“With v-belts, chains and couplings no longer required, the internal drive design drum motor, has efficiency gains of up to 30% and lower operating costs,” he said.

“Reliability and longevity of conveyor drives pose challenges for belt conveyors to operate in harsh and abrasive environments and failure is ground zero for loss of production. The latest Van der Graaf GrizzlyDrive drum motor with IronGrip lagging is developed specifically to operate in these extreme environments.”

The GrizzlyDrive is available from 3-50 horsepower and 8.5″ to 42″ diameter, with thepatented IronGrip high performance lagging design engineered for harsh and vibratory applications, according to Van der Graaf.