Ongoing sanitary design advances for snack and bakery equipment

[...]

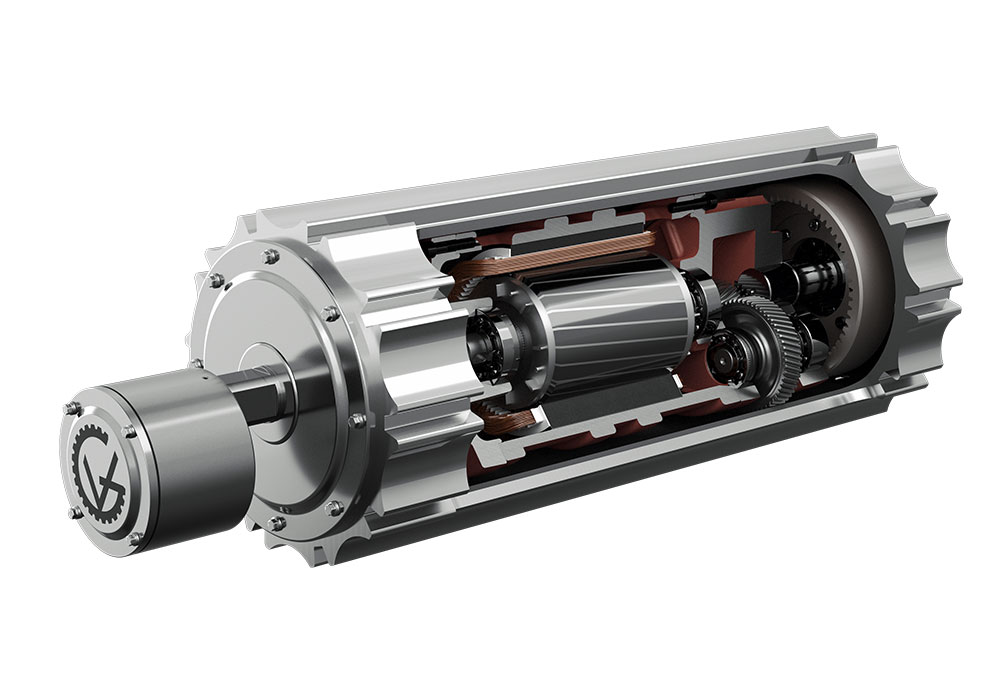

Alex Kanaris, president Van der Graaf, Brampton, Ontario, says his company designs motors to the standards of the meat and poultry industries, which makes them perfectly applicable to snack foods and other food applications. “We have been designing our products strictly for sanitation, working within USDA regulations,” he says, noting that in processing facilities that do meat, the ground zero for bacteria sanitation is on the belts and drives. “We said, ‘OK, look at what is acceptable today.’ It’s not really sanitary, especially for meat and poultry. You have a lot of byproduct accumulation in those areas.”

To solve that dilemma, Van der Graaf designed the SSV Sanitary Drum Motor in such a way that sprockets are unnecessary, and the motor and gearbox can be placed inside the frame of the machine, Kanaris says. “By not using sprockets, we avoid a couple of things. There’s no foreign material contamination, because there’s nothing to break, and there’s better sanitation, because there are no crevices or anything that can promote bacteria buildup.”

Another benefit of the design is for applications that need to be washed down or sanitized, the time involved is cut by about two-thirds, notes Kanaris. “It addresses sanitation, efficiency and safety. Those are the three legs in our stool.”

View original article