Sanitary Drum Motors from VDG create ROI

Van der Graaf, a global manufacturer of drum motors located in Brampton, Ont., says its line of SSV series sanitary drum motors is available in five versions: TM100, TM113, TM127, TM160, and the TM215, with drum diameter and horsepower differences, but each advancing food safety and worker safety. Other options are available for each of these drums.

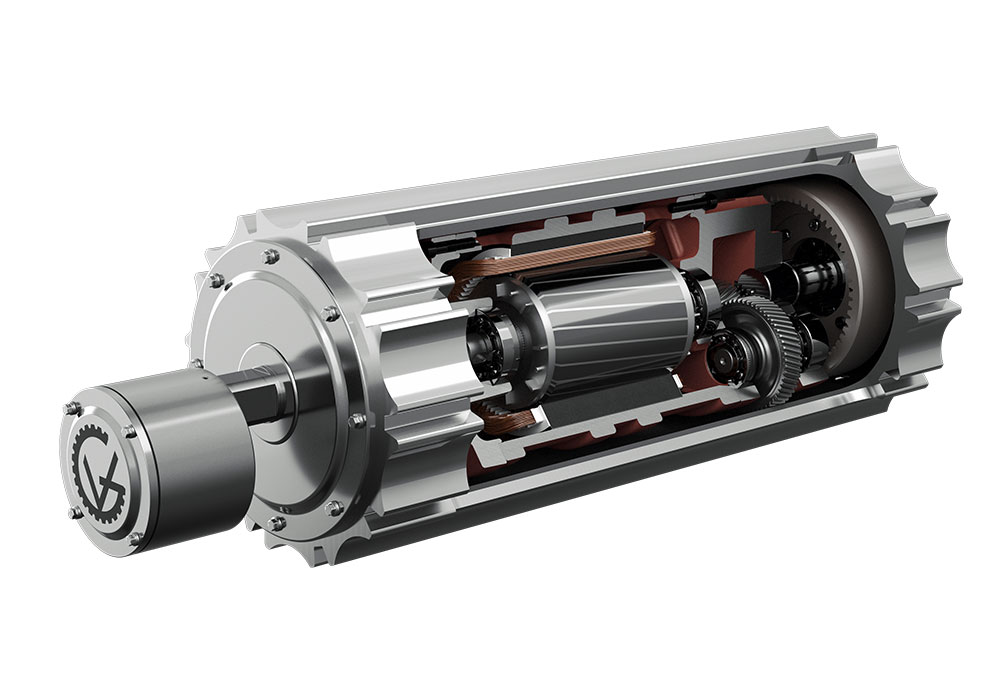

The drum motor is a one component conveyor drive where the motor, gear drive and all moving parts are enclosed inside the drum. The motor and gears operate in a sealed oil bath ensuring proper lubrication and cooling. With no external motor, gear reducer, sprockets, chain or OSHA (Occupational Safety and Health Administration)-required chain guard, no external component maintenance is required.

Designed and engineered specifically for the food industry, the USDA-approved sanitary series drum motors meet and exceed the highest level of sanitation requirements. The all-stainless steel construction, IP69K sealing system can withstand up to 3,000 psi (pounds per square inch) of wash down pressure.

Because the systems have no moving parts, worker safety is increased. Other benefits include: improved sanitation via reduced harbouring areas, reduced maintenance necessity, which leads to drum motor efficiency, and thus a faster return on investment.

With a total operating cost lower than other conventional drive systems, the Van der Graaf drum motor will pay for itself by its design, engineering and installation time, though true ROI is achieved through electrical and mechanical efficiencies that create lower operating for increased profits.

Van der Graaf president Alex Kanaris says his company designs motors to the standards of the meat and poultry industries, which makes them perfectly applicable to snack foods and other food applications.

View original article